Downhole Drilling Detectors

Measurement-While-Drilling • Logging-While-Drilling • Wireline

As the upstream oil and gas market continues to evolve to faster drilling and advanced measurements, Reuter-Stokes has been at the forefront of delivering customized formation evaluation and directional sensor measurements for oilfield services companies and Measurement While Drilling / Logging While Drilling (MWD/LWD) system OEMs around the globe.

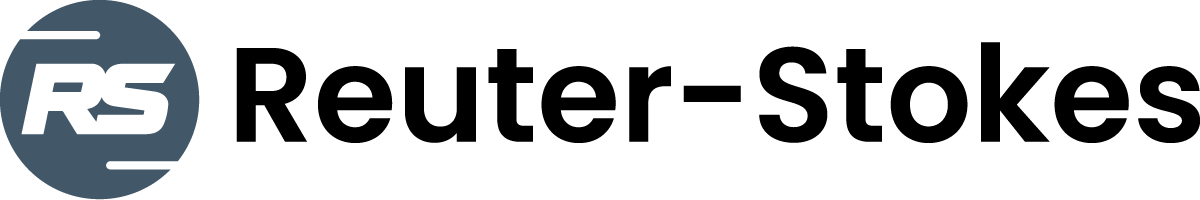

Reuter-Stokes manufactures downhole sensors and electronics to support your downhole operations, including scintillation detectors for gamma-ray and spectroscopy applications and neutron detection to confirm you have the best data for your formation evaluation.

Our engineers are ready to customize a solution to solve your latest drilling challenge so you can accomplish more in the field.

Core capabilities

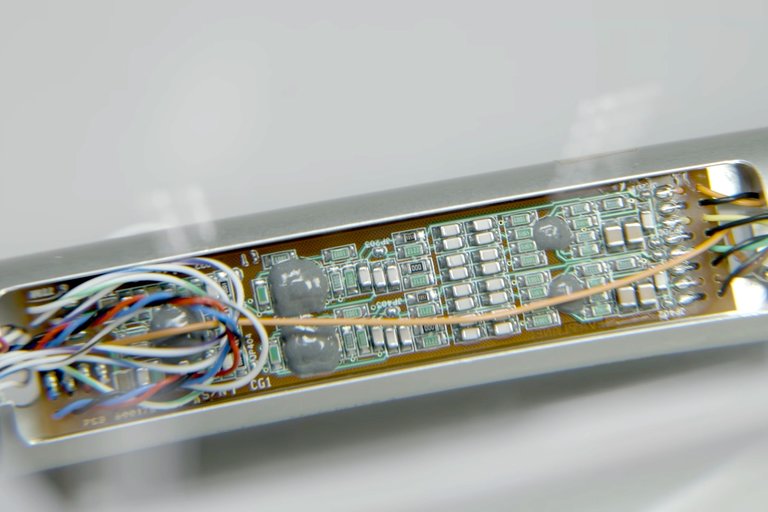

Coil winding for fluxgate manufacturing

Scintillation crystal machining and polishing

Low moisture/oxygen glove boxes

Patented optical coupler technology

Custom TIG welding equipment

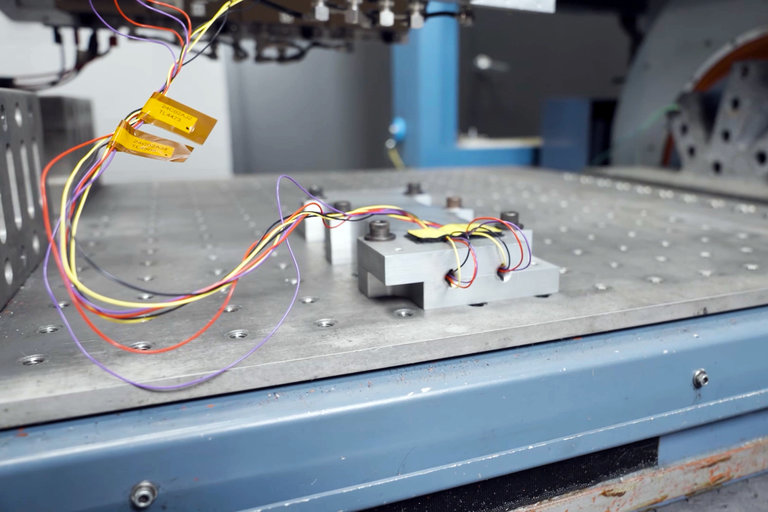

Complete radiation test capability

Brazing furnace for sapphire optical components and ceramics for metal brazing

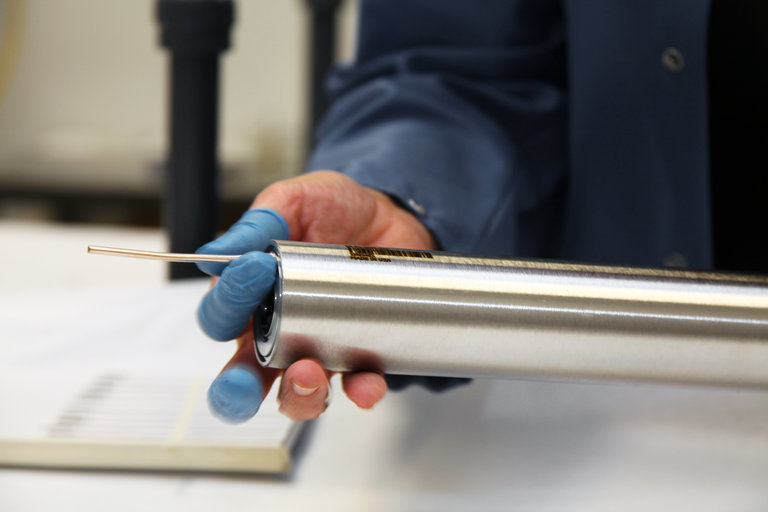

We engineer and build sensors to withstand high temperatures, shocks, and vibrations. We also design for high sensitivity, low power usage, and operation in small spaces near the bit for optimal precision of measurement.

While Reuter-Stokes has a wide selection of standard products, most of our gamma sensors and neutron detectors start as custom designs. Customization is a collaborative process with our customers to ensure the final product meets the rigors of a given application.

Our objective is to deliver improvements you can measure – in efficiency, reliability, availability, and performance.

Gamma Sensors

For gross counting, spectral, and density gamma sensing.

Reuter-Stokes' gamma sensors provide geologists and operators with the precise measurements required for accurate formation location and identification.

- Sodium Iodide (NaI) scintillators with open configuration options.

- Crystal packages optimized for light output, energy resolution and sensitivity.

- Shock survivability to 1,000 g

- Random vibration rating of 20 grms

- Operating temperatures to 200˚C (392˚F)

- Customize crystal size, mounting, interface adaptations or integrated radioactive calibration sources

Neutron Detectors

For gross counting neutron and neutron porosity detection

Thermal and epi-thermal detectors based on the pioneering Reuter-Stokes Helium-3 proportional tube design.

- Drilling Application Sensors from 0.75 in. to 1.00 in. diameter

- Wireline Application Sensors from 1.00 in. to 2.50 in. diameter

- Easy parallel operation and good gamma discrimination in virtually any downhole setting.

- Patented anode suspension minimizes shock-induced false counts.

- Customizable sizes, gas mixtures, electrical terminations, and mechanical interfaces.

Orientation Modules

Digital and Analog, Fluxgates

Our most compact downhole survey technology, built to double the mean time between calibrations.

- Flexibility: Innovative electronics and packaging result in smaller orientation modules with borehole survey technology designed to fit into the smallest tools.

- Reliability: Accurate inclination and azimuth survey data.

- Lower cost of ownership: Proven durability with an extended lifespan and minimal downhole power consumption.

- Minimizes operational costs associated with downhole batteries and enables the horizontal drilling techniques required for unconventional well development.

Quality by design

1,600 square foot dry room

For scintillation crystal processing

2,800 square foot lab

Non-magnetic total field calibration building

Rigorous testing

At every stage of the design, qualification and production processes.