Nuclear Instrumentation

Boiling Water Reactors • Pressurized Water Reactors • Small Modular Reactors

Beginning with the first Reuter-Stokes Helium-3 neutron detector in 1956 that led to the development of Local Power Range Monitors (LPRMs), we have been committed to quality and excellence in nuclear instrumentation ever since.

Today, Reuter-Stokes detectors are in every operational Boiling Water Reactor globally.

Our nuclear quality certifications include:

- 10 CFR 50 Appendix B Quality Program

- ISO9001:2015

- ASME "N" Stamp

- NPT-type certificate holder; Allows us to design and manufacture Section III, Class 1 and pressure boundary components.

Reuter-Stokes develops sensors based on our decades of experience with ex-core and in-core neutron monitoring detectors and our expertise in neutron detection instrumentation. We also offer industry-leading 10B coating performance.

Boron-10 coating lining a detector

Reuter-Stokes' engineers, physicists, chemists, and materials scientists can customize our catalog to suit your specific needs. We design for a variety of lifetime operating scenarios.

Continuous in-situ sensor data provides optimum visibility into equipment and process functions for safety and efficiency.

- Fission Chambers

- Ionization Chambers

- Proportional Counters

- Gamma Thermometers

- Ionization Chambers

- Scintillation Detectors

- GM Tube-Based Detectors

- Scintillation Crystal-Based Detectors

- Ionization Chambers

- Movable Fission Chambers

- Movable Ionization Chambers

- Drive Mechanisms

- Gear Boxes

- Motors

- Integrated mineral-insulated cabling

- Detector Housings

- Integrated Moderator

• Gamma and neutron TIPs for LPRM sensor calibration and axial flux mapping.

• With the improved accuracy of Gamma TIPs, there is also the potential for extending time intervals between LPRM calibrations.

• Mechanical Drive Equipment: TIP drive and indexing mechanisms, tubing and guide tube/valve assemblies.

• Miniature fission chambers for use with local and average power range monitoring.

• Designed, manufactured and factory-tested to conform to American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code, Section III, Nuclear Power Plant Components.

• Reuter-Stokes has several decades of experience manufacturing gamma thermometers which have been used for calibrating LPRM fission chamber detectors in Boiling Water Reactor (BWR) plant designs.

• Startup instrumentation sensors are calibrated for optimal measurements from below source level to ~10% of rated reactor power.

• Wide Range Neutron Monitor (WRNM) combines functionality of SRM and IRM detectors into one solution.

• Mechanical Drive Equipment: SRM/IRM detector drive mounts, motor modules, flex shafts, drive tubes, and shuttle tubes.

Designed, manufactured and factory-tested to conform to American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code, Section III, Nuclear Power Plant Components.

Design options for measurement without or during hydrogen injection for water chemistry monitoring.

Products, such as cabling and connectors, to enhance safety and efficiency during undervessel SRM, IRM, LPRM and WRNM detector work.

Designed for durability, accuracy, time savings, and ALARA savings.

Ex-Core Fission Chambers for Pressurized Water Reactors

Reuter-Stokes' fission chambers measure neutron flux in the source range, intermediate range, wide range (source and intermediate), or power range to help manage, control, and protect the nuclear reactor.

We offer fission chambers in both guarded and unguarded styles. The guarded fission chambers are particularly well suited to applications where low signal and anticipated operational environments demand the highest level of immunity against electromagnetic interference.

To help ensure that the critical signal of the fission chamber arrives to the control room, we can utilize safety-related mineral-insulated signal transmission cables (coaxial and tri-axial), as well as safety-related electrical connectors. Both cables and connectors are designed and manufactured to provide high levels of electrical isolation under the demanding environmental conditions present in containment.

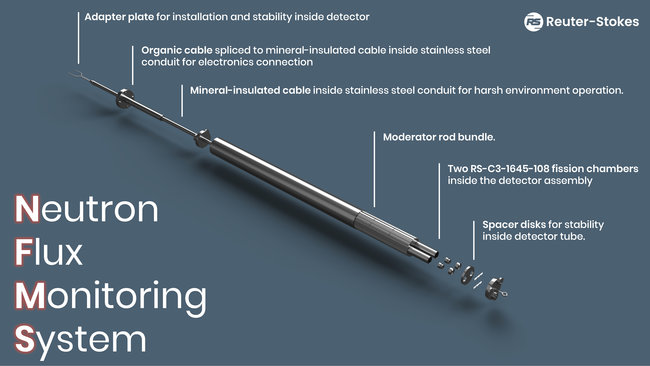

Moveable-in-Core (MIC) Detectors

Building on our vast success providing sensors and monitoring equipment to BWR customers, we introduced our Movable In-Core (MIC) detector in 1968 to be used by PWR utilities. Able to map the thermal neutron flux in the water gap between adjacent fuel bundles, our MIC detector has been installed in power plants worldwide.

Our precisely matched, machined, and bonded MIC components increase reliability by minimizing the possibility of detector failure resulting from installation and removal. This means exact radiation readings when you need them, every time. Reuter-Stokes MIC detectors are compatible with all equipment with all equipment vendors and can perform as direct replacements for current movable in-core probes.

MIC probes are available in right handed or left handed models and in custom lengths.

Combining the electronics of reactor controls, Reuter-Stokes provides a customized, comprehensive solution for all of your BWR, PWR, and SMR nuclear instrumentation and control needs.

The unique uranium coated miniature fission chamber and mineral insulated cable technology of the MIC enables detection of the core thermal neutron radiation levels by traversing the active fuel region and producing a direct current that is proportional to the neutron flux in the water gap. The accurate signal of the MIC, enabled by the ceramic to metal seal that isolates the detector and cable assembly, eliminates variation at temperature from gas expansion and provides a signal that is precise and repeatable over hundreds of flux scans. This allows greater confidence in the neutron monitoring system operation.

Superior insulation resistance at temperature in the Reuter-Stokes MIC probes aids in exact flux measurement by minimizing leakage currents. This proven design permits usage of the detector over a wide range of temperatures, decreasing the need for frequent replacements. The long detector lifetime contributes to increased operation efficiency and decreased maintenance costs.